First laundry completely controlled by WinWash 2.0

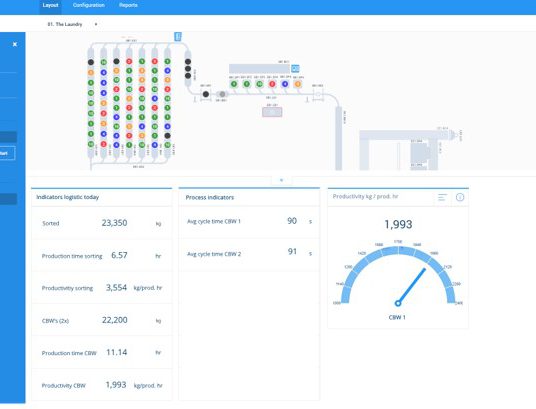

Good news! After much development, testing, discussion and a beta version, we have fully equipped a laundry with WinWash 2.0. With the delivery of the bag rail systems, the soiled laundry sort and the expedition system to our customer Kellner’s new laundry, the role of WinWash 2.0 as a logistics system is fulfilling its potential.

Our role as a system integrator was very important as this step forward involved seamlessly integrating in WinWash 2.0 not only the data transfer but also the wash tunnel, dryers and ironers (all by Jensen).

Creating scope for fully automatic item counts also represents another step towards the phasing out of manual operations. See the following situation, for example:

Automatically, WinWash 2.0 tells the ironers – or the towelling folders – the folding programme that is right for the product. Then, at the stacker output, the correct item – which is also customer-specific – is determined together with the quantity. Together, this means that manual counting is gradually becoming a thing of the past and that WinWash 2.0 is helping to reduce your administrative workload.

As well as working to achieve this success, we are fully involved in producing control systems (and visualisation and settings) for wash tunnels and dryers in WinWash 2.0. Over the course of 2019, as laundries start making use of this option, a fully coherent logistics system will emerge.