Suboptimization in laundries: silent killer of return

“A silent killer of return,” Jacco van Riessen calls suboptimization in laundries. The sales manager of WSP Systems is clear about it. “Many laundries can achieve five to twenty per cent of productivity increase with their existing laundry layout. People don’t need to work harder and the machines do not need more capacity, but they must function as one system. Manage your laundry as a chain.”

Managing a laundry has become top sport. Price pressure in the market requires control of return to the tiniest detail. While volumes grow, customers continue to ask for customized services. People and machines in the laundry must deliver maximum performance.

Magic trick?

“That is what happens in most laundries,” says Van Riessen. “As independent system integrators we lay out laundries. Worldwide we encounter wonderful companies, led by entrepreneurs with a vision. Companies that cannot imagine that another five to twenty per cent of productivity gain is there for the taking. But it is. The secret? No magic trick, but automate your laundry and manage it as a logistic chain.”

Complex logistic puzzle

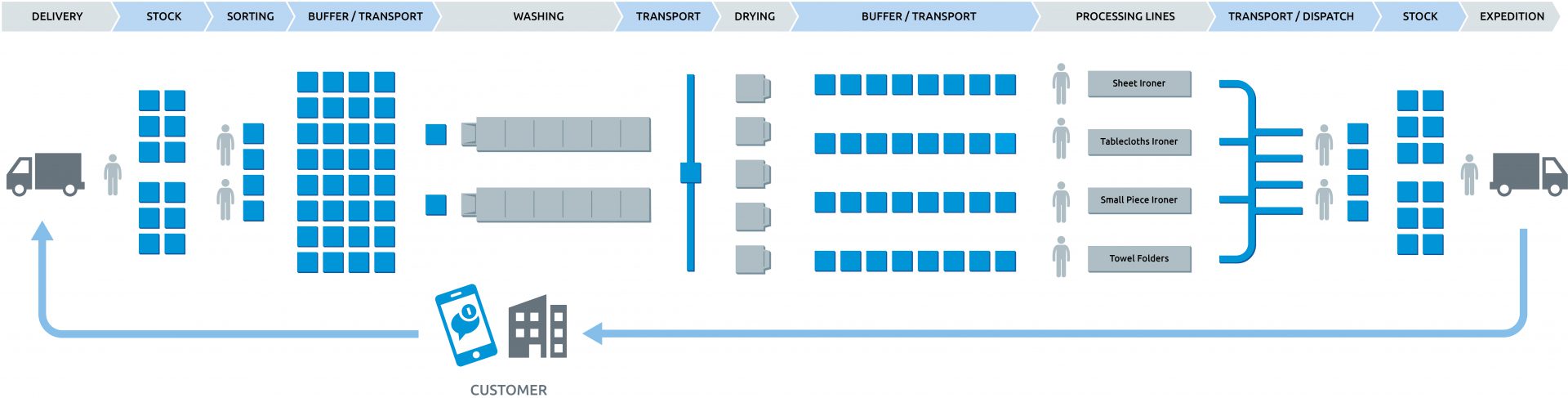

Van Riessen explains the vision of WSP Systems that has led to the development of a unique, integrated management system. “Laundries consist of various islands. Specific steps in the processing of laundry, with specific machines and specific teams. Apparently, the laundry goes linearly through these islands, from sorting to shipping. Each islands does its best. But it is suboptimization. In reality, the laundry is a complex logistic puzzle that is hardly overlookable. Return leaks away not on, but between the islands.”

Symptoms

The symptoms seem harmless. Inefficient loading causes delays in the wash tubes. Peaks in the supply of fully dry laundry causes obstruction at the dryers. Costly secondary deliveries are required to supply customers. All in all, there are lots of everyday inefficiencies.

Toward central management

“The dream of a continuous process, in which the capacity of all people and machines is optimally used, will remain a dream,” says Van Riessen, “Until you implement a smart system that oversees the entire chain. A system that rapidly and in real time determines and automatically controls the ideal route or each batch of laundry through the laundry space (WinWash 2.0, ed.). Central optimisation of your laundry as one logistic chain brings unexpectedly much rest and return.”

Are there any impediments to ending suboptimization? Van Riessen considers this and smiles. “Technically there are hardly any barriers. WinWash 2.0 does not only communicate with machines of all brands, but also with the higher-level systems, such as route planning software and linen management systems. The greatest impediment may be people. People who can hardly imagine that organization can be even better. But we can be brief about this. A quick scan through our consultants and a worked-out business case show what can be gained. Chain thinking pays off!”