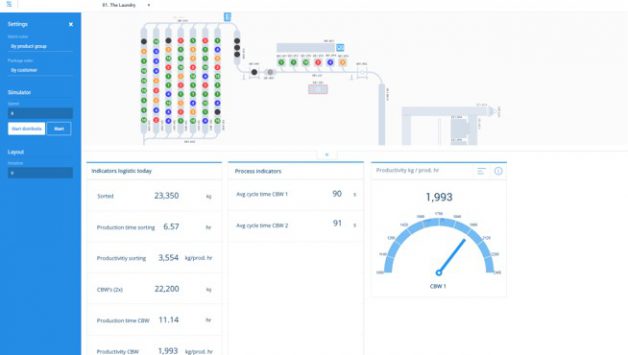

WinWash 2.0

The operating system that ensures integral efficiency in the laundry

Modern machines with huge capacities, motivated employees, experienced managers. They do not guarantee maximum performance if they function as separate islands. Maximum performance can only be achieved if you organise your laundry as a chain. As one whole. As a system in which batches of laundry flow through your laundry. Without downtime, delays, blockages, countless container movements and costly subsequent deliveries.

All you need is WinWash. A control system that plans your production at a batch level. A platform that allows you to integrate third-party systems (e.g. machine manufacturers) into one unbeatable production manager. Fully automated. With WinWash, a well-run laundry can achieve 10 to 20 percent productivity gains.

Core functionalities are:

- Planning

- Controlling

- Information

- Reporting

- Simulation

- Integration

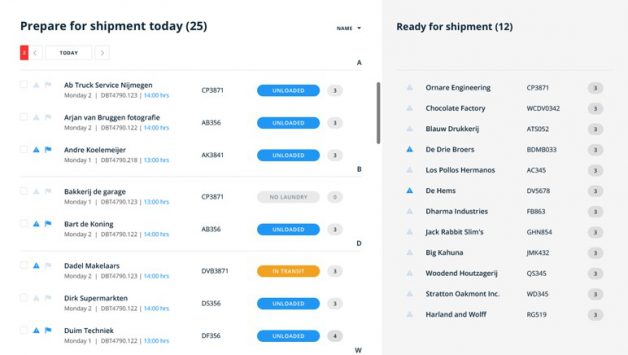

The initial concept is based on the LEAN and Just in Time principles: the required production (or orders) are leading in the full supply chain. From the collection of soiled laundry at the customer

premises to the delivery of clean linen.

Would you like to know what WinWash can do your laundry operation? We would be happy to develop some ideas with you!

Get in touch with us